BOSCH

3842543246

VF plus: WT system accessories

$0.26

BOSCH

MATERIAL: 3842543246

SUMMARY: VF plus: WT system accessories

Quantity in stock: 0

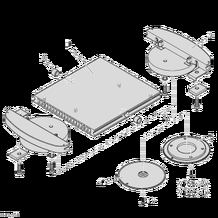

For transporting products that are not suitable for accumulation operation or are unstable due to their geometry

Max. transport speed for operation with workpiece pallets: vN = 18 m/min Workpiece pallet wear pads either made of: Steel, for use in harsh environments PE, for use in clean environments Workpiece pallet load (workpiece, support, etc.) Size 65: 8 kg Size 90: 8 kg The modular concept allows for workpiece pallet lengths of up to 500 mm*. With centering bushings for positioning in the positioning unit.* For workpiece pallet with L > 300 mm, combine two 90° curve wheels with intermediate section (min. 200 mm).

For workpiece pallet with L < 300 mm, use 180° curve wheel

Minimum length of the workpiece pallets: Size 65: Lmin = 76 mm Size 90: Lmin = 114 mm Minimum length of the workpiece pallets in order to incorporate the positioning unit: Size 65: Lmin = 125 mm Size 90: Lmin = 125 mm Minimum length WT for passive bridge: L ≥ 300 mm

Material:

WT plate: aluminum; natural, anodized End pieces: PA; black Workpiece pallet wear pads: steel; stainless, HV ≥ 480 or PEScrew

PE wear pad

Steel wear pad

VarioFlow workpiece pallet (WT)

Optimum center of gravity range for smooth operation

Workpiece pallet VFplus 65, VFplus 90