BOSCH REXROTH

R901374869

$416.30 USD

- BOSCH REXROTH

- Material:R901374869

- Model:Z2S6-1-6X/V/60

Quantity in stock: 0

The Bosch Rexroth Z2S6-1-6X/V/60 (R901374869) is a high-quality isolator valve designed for efficient hydraulic flow control within a range of systems. This sandwich plate valve is specifically engineered to allow free flow from A to A or B to B, while securely blocking the opposite direction, ensuring leakage-free blocking even during extended periods of inactivity. Its design incorporates a control spool that moves to open the ball seat valve and displace the poppet, enabling fluid to flow from B to B when required. The Z2S6-1-6X/V/60 features a preopening function that dampens decompression of pressurized liquid, thereby minimizing potential switching shocks and reducing wear on components and noise levels. The two-stage setup with an increased control open ratio ensures secure unloading even at low pilot pressures. Crafted for reliability, this model boasts compatibility with vertical stacking applications and conforms to DIN form A without locating hole, as well as ISO with locating hole for versatile installation options. It offers various cracking pressures that can be specified through ordering codes and also includes the option for preopening. For maintenance or system customization, check valve installation sets are available individually. With its robust construction, the Z2S6-1-6X/V/60 can withstand maximum operating pressures of up to 350 bars and handle maximum flow rates of 60 liters per minute. Users can request special versions tailored to specific requirements. Whether used in industrial machinery or mobile applications, this Bosch Rexroth isolator valve stands out for its precision engineering and adaptability in controlling hydraulic flow securely and efficiently.

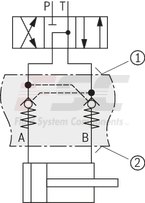

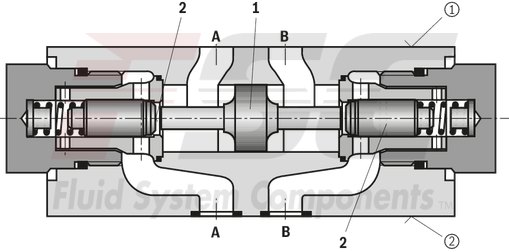

The isolator valve type Z2S is a releasable check valve in sandwich plate design.

It is used for the leakage-free blocking of one or two actuator ports, also in case of longer standstill times.

In direction A① to A② or B① to B②, there is a free flow; in the opposite direction, the flow is blocked.

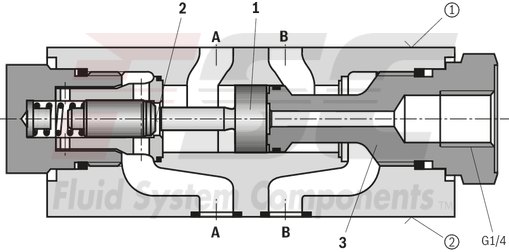

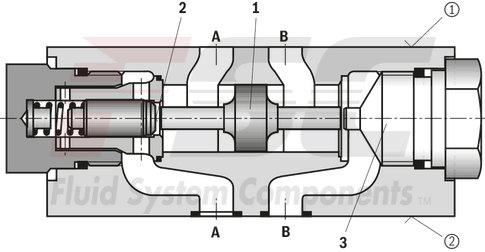

If, for example, there is a flow through the valve in direction A① to A②, the control spool (1) is moved in the direction of the B side, opens the ball seat valve (2) and then pushes the poppet (3) off its seat. Hydraulic fluid can now flow from B➁ to B➀.

In order to allow the ball seat valve (2) to be safely closed, the control spool (1) must be hydraulically unloaded (see circuit example).

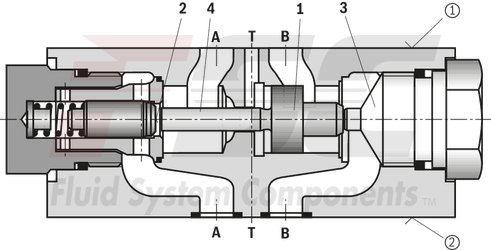

Pre-opening

Due to the pre-opening, there is a damped decompression of the pressurized liquid. Thus, possible switching shocks are avoided. The two-stage set-up with an increased control open ratio means even low pilot pressure can be unloaded securely.

Notice:

In valves without pre-opening, sudden unloading of pent-up pressure volume may occur. Resulting switching shocks may lead to premature wear on installed components, as well as noise formation.

|

1 |

Control spool, area A2 |

|

2 |

Poppet, area A1 |

|

3 |

Stop |

Type Z2S 6 A…SO40

Type Z2S 6 A…SO60

|

1 |

Control spool, area A2 |

|

2 |

Poppet, area A1 |

|

3 |

Stop |

|

4 |

Control spool, area A4 |

|

5 |

Pre-opening, area A3 |

Type Z2S 6 -…SO55 (with pre-opening)

1) Corrosion-resistant surface on request: e.g."J50" thick film passivated (DIN 50979 Fe//Zn8//Cn//T0)

2) Locking pin ISO 8752-3x8-St, material no. R900005694 (separate order)

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

||

|

Z2S |

6 |

– |

6X |

/ |

* |

|

01 |

Check valve, Sandwich plate design |

Z2S |

|

02 |

Size 6 |

6 |

|

Leakage-free blocking |

||

|

03 |

In channel A and B |

– |

|

In channel A |

A |

|

|

In channel B |

B |

|

|

Cracking pressure |

||

|

04 |

1,5 bar |

1 |

|

3 bar |

2 |

|

|

6 bar |

3 |

|

|

05 |

Component series 60 … 69 (60 … 69: unchanged installation and connection dimensions) |

6X |

|

06 |

Surface without corrosion resistance 1) |

no code |

|

Seal material |

||

|

07 |

NBR seals |

no code |

|

FKM seals |

V |

|

|

The selection is dependent on the operating parameters (hydraulic fluid, temperature, etc.)! |

||

|

Locating hole |

||

|

08 |

no code |

|

|

With locating hole |

/60 |

|

|

With locating hole and locking pin ISO 8752-3x8-St 2) |

/62 |

|

|

Special version |

||

|

09 |

Without special version |

no code |

|

Control open by external port G1/4 (only version "A" and "B") |

SO40 |

|

|

With pre-opening |

SO55 |

|

|

Control spool unloaded to port T |

SO60 |

|

|

With pre-opening and control open from channel P |

SO150 |

|

|

Symbols (examples) see "Symbols/Circuit diagrams" |

||

|

10 |

Further details in the plain text |

* |

general

|

Size |

6 | ||

|

Weight |

kg |

0.8 | |

|

Installation position |

any | ||

|

Ambient temperature range |

NBR seals |

°C |

-30 … +80 |

|

FKM seals |

°C |

-20 … +80 | |

hydraulic

|

Size |

6 | ||

|

Maximum operating pressure |

bar |

315 | |

|

Cracking pressure 1) |

bar |

1.5 / 3 / 6 | |

|

Maximum flow |

l/min |

60 | |

|

Direction of flow |

see symbols | ||

|

Hydraulic fluid |

see table | ||

|

Hydraulic fluid temperature range (NBR seals) |

°C |

-30 … +80 | |

|

Hydraulic fluid temperature range (FKM seals) |

°C |

-20 … +80 | |

|

Viscosity range |

mm²/s |

2.8 … 500 | |

|

Maximum admissible degree of contamination of the hydraulic fluid 2) |

Class 20/18/15 according to ISO 4406 (c) | ||

|

Area ratio |

Without pre-opening |

A1/A2 ~ 1/3.5 (see sectional drawing) | |

|

With pre-opening |

A3/A2 ~ 1/12.5 (see sectional drawing) | ||

|

Version "SO60" |

A1/A4 ~ 1/7 (see sectional drawing) | ||

| 1) | in free direction |

| 2) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Selection of optimal sealing material also depends on the type of hydraulic fluid used.

For applications outside these parameters, please consult us!

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

|

|

Mineral oils |

HL, HLP, HLPD |

NBR, FKM |

DIN 51524 |

|

|

Bio-degradable |

Insoluble in water |

HETG |

NBR, FKM |

VDMA 24568 |

|

HEES |

FKM |

|||

|

Soluble in water |

HEPG |

FKM |

VDMA 24568 |

|

|

Flame-resistant |

Water-free |

HFDU, HFDR |

FKM |

ISO 12922 |

|

Containing water |

HFC (Fuchs Hydrotherm 46M, Petrofer Ultra Safe 620) |

NBR |

ISO 12922 |

|

Important information on hydraulic fluids!For further information and data on the use of other hydraulic fluids, please refer to data sheet 90220 or contact us! There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.)! The flash point of the hydraulic fluid used must be 40 K higher than the maximum solenoid surface temperature.Flame-resistant – containing water: Maximum operating pressure 210 bar Maximum hydraulic fluid temperature 60 °C Life cycle compared to operation with mineral oil HL, HLP 30 to 100 % |

||||

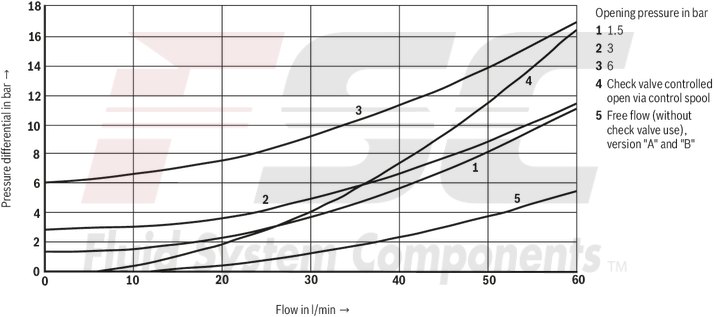

(measured with HLP46, ϑOil = 40 ±5 °C)

Δp-qV characteristic curves

Δp-qV characteristic curves

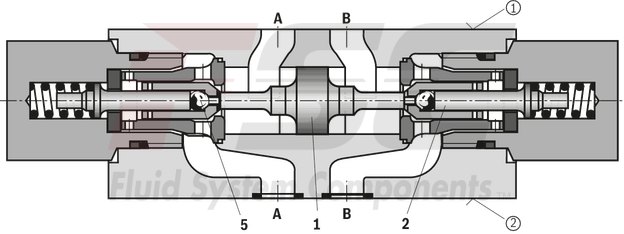

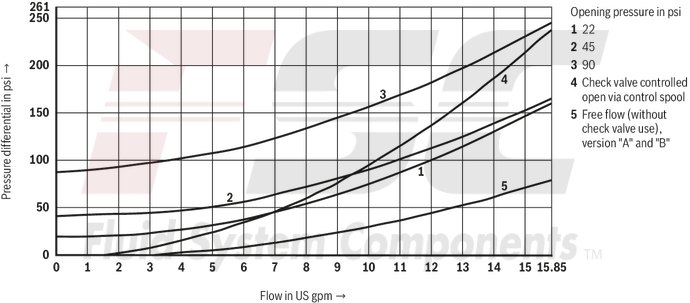

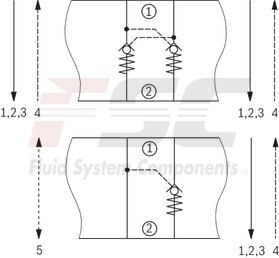

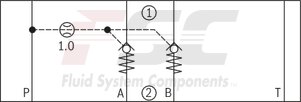

Circuit example, schematic

|

① |

component side |

|

② |

plate side |

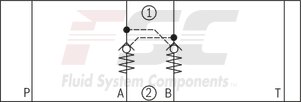

Type Z2S 6 A…

Type Z2S 6 -… and Z2S 6 -…SO55

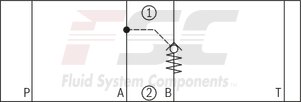

Type Z2S 6 B…

Type Z2S 6 A…SO40

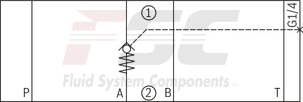

Type Z2S 6 A…SO60

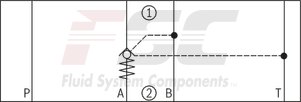

Type Z2S 6 -…SO150

|

➀ |

component side |

|

➁ |

plate side |

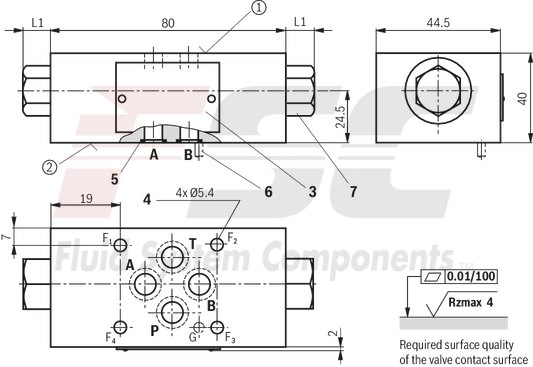

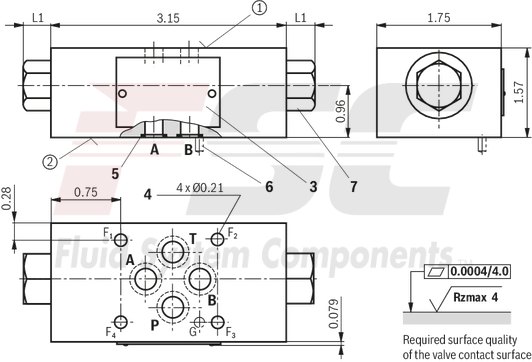

Dimensions in mm

Dimensions in mm

|

Type |

L1 |

|

mm |

|

| Z2S 6...ohne Bez. | 11 |

| Z2S 6...SO40 | 11 |

| Z2S 6...SO55 |

11 1) 21.5 1) |

| Z2S 6...SO60 | 11 |

| Z2S 6...SO150 | 21.5 |

| 1) | Maximum dimension on the side of the check valve cartridge |

|

➀ |

component side – porting pattern according to DIN 24340 form A (without locating hole), or ISO 4401-03-02-0-05 (with locating hole Ø4 x 4 mm deep) and NFPA T3.5.1 R2-2002 D03 |

|

➁ |

plate side – porting pattern according to DIN 24340 form A (without locating hole), or ISO 4401-03-02-0-05 (with locating hole for locking pin ISO 8752-3x8-St; version "/60" and "/62") and NFPA T3.5.1 R2-2002 D03 |

|

3 |

Name plate |

|

4 |

Through hole for valve mounting |

|

5 |

Identical seal rings for ports A, B, P, and T |

|

6 |

Locking pin ISO 8752-3x8-St (only version "/62") |

|

7 |

Plug screw SW22 |

Valve mounting screws (separate order)

4 hexagon socket head cap screws ISO 4762 - M5 - 10.9

4 hexagon socket head cap screws N10-24 UNC

Notice!

The length of the valve mounting screws of the sandwich plate valve must be selected according to the components mounted under and over the isolator valve.

Depending on the application, screw type and tightening torque must be adjusted to the circumstances.

Please ask Rexroth for screws with the required length.

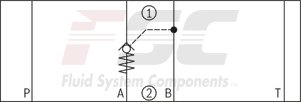

Type Z2S 6 -… (with pre-opening)

Type Z2S 6 A…

|

➀ |

component side |

|

➁ |

plate side |