BOSCH REXROTH

R978049363

$11,622.24 USD

- BOSCH REXROTH

- Material:R978049363

- Model:SYDFE1-2X/100R-PKC62KC5-OOOO-AOXOXXX1834

Due to extremely high demand, please call 920-337-0234 for availability

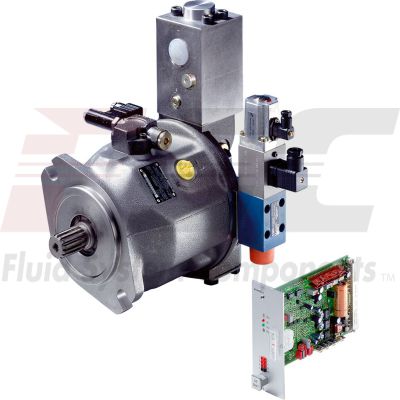

The Bosch Rexroth SYDFE1-2X/100R-PKC62KC5-OOOO-AOXOXXX1834 (R978049363) is a state-of-the-art hydraulic pump system designed for precise control and efficiency in demanding applications. This axial piston variable displacement pump features an external analog electronics system that allows for the fine-tuning of swivel angle and pressure control, making it suitable for a master-slave setup. With a nominal pressure of 280 bar and maximum operating pressure of 350 bar, the pump ensures robust performance in various hydraulic operations. The SYDFE1-2X/100R-PKC62KC5-OOOO-AOXOXXX1834 integrates a range of components including a pilot valve with an inductive position transducer for valve position sensing and an actuating piston to facilitate accurate control. The proportional solenoid, valve spool, drive shaft, and connection flange are all expertly crafted to work seamlessly with the pump's functionality. It also includes a swivel angle position sensor that contributes to its precise operation. This model operates with an analog interface for communication, providing flexibility in system integration. The speed ranges from a minimum to maximum as specified by the user's requirements, while the displacement type is variable to accommodate different flow rates. Its clockwise rotation direction ensures compatibility with standard system configurations. The SYDFE1-2X/100R-PKC62KC5-OOOO-AOXOXXX1834 operates on a supply voltage of 24 VDC and is designed without through-drive capability. It features FKM seals for enhanced durability against harsh fluids like HLP hydraulic fluid. Its robust construction is evident in its weight specification and ISO-hole assembly design, which underscores its reliability and ease of installation. Overall, this Bosch Rexroth pump system exemplifies precision engineering with its comprehensive set of features tailored for high-performance hydraulic applications requiring meticulous pressure and flow control.

Pump A10VSO BR31 with external analog electronics

Pump system, maximum operating pressure 280 bar, size 100, functionality: Swivel angle, pressure control, master/slave

Unpacked Weight: 57 kg

|

1 |

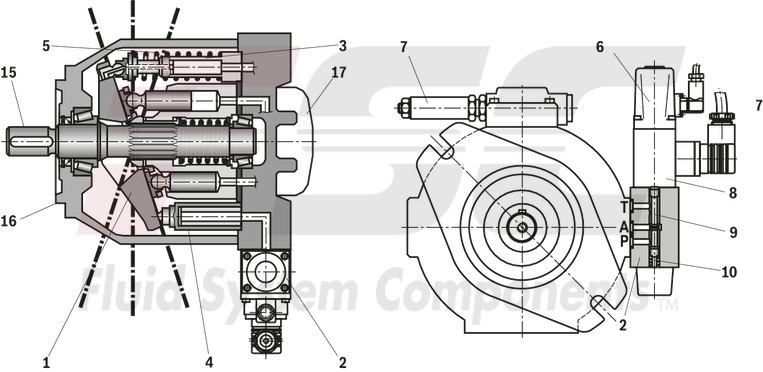

Swash plate |

|

2 |

Pilot valve |

|

3 |

Counter piston |

|

4 |

Actuating piston |

|

5 |

Spring |

|

6 |

Inductive position transducer for valve position |

|

7 |

Swivel angle position sensor |

|

8 |

Proportional solenoid |

|

9 |

Valve spool |

|

10 |

Spring |

|

15 |

Drive shaft |

|

16 |

Connection flange |

|

17 |

Subplate, optionally with through-drive |

| Own supply |

| Component series 2X |

| 100 cm³ |

| Nominal pressure 280 bar |

| Communication: analog |

| Maximum operating pressure 280 bar |

| External control electronics |

| Function: Pressure, swivel angle control, torque limitation, master-slave |

| Size 18 … 100 |

| With axial piston variable displacement pump A10VSO.../31 |

| Data Sheet | Download Data Sheet |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Max. pressure | 280 |

| Shaft end | Fitting key shaft |

| Electrical connection description | Valve connector, valve position transducer connector, SWA connector |

| Size | 100 |

| Speed min. | 250 |

| Productgroup ID | 9,10,11,12,13,14 |

| Speed max. | 2000 |

| Mounting flange | ISO 2-hole |

| Max. flow | 200 |

| Displacement type | variable |

| Direction of rotation | clockwise rotation |

| Supply voltage | 24 VDC |

| Through-drive | without |

| Weight | 57 |

| Seals | FKM |

| Connectivity | Analog |

| Hydraulic fluid | HLP |

| Hydraulic fluid | HLP |

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

12 |

13 |

14 |

|||||

|

SYDFE1-2X |

/ |

– |

P |

12 |

– |

– |

0 |

XX0XX |

– |

* |

|

Pump of the SYDFE control system |

|||||||||

|

Series |

|||||||||

|

01 |

Control system for external analog electronics (separate order) |

SYDFE1-2X |

|||||||

|

Pump combinations (see order example) |

SY2DFE.-2X, |

||||||||

|

Size |

018 |

028 |

045 |

071 |

100 |

140 |

|||

|

02 |

Displacement cm³ |

18 |

28 |

45 |

71 |

100 |

140 |

||

|

Direction of rotation looking at the drive shaft |

|||||||||

|

03 |

Right |

● |

● |

● |

● |

● |

● |

R |

|

|

Left |

● |

● |

● |

● |

● |

● |

L |

||

|

Hydraulic fluid |

|||||||||

|

04 |

Mineral oil according to DIN 51524 (HL/HLP) |

● |

● |

● |

● |

● |

● |

P |

|

|

Drive shaft variant |

|||||||||

|

05 |

Cylindrical with fitting key DIN 6885 (not in connection with through-drive) |

Ø18 |

Ø22 |

Ø25 |

Ø32 |

Ø40 |

Ø45 |

P |

|

|

Splined shaft profile SAE J 744 1) |

3/4" |

– |

– |

– |

1 1/2" |

1 3/4" |

S |

||

|

Splined shaft profile SAE J 744 (higher torque) |

– |

7/8" |

1" |

1 1/4" |

– |

– |

R |

||

|

Connection flange (centering in mm) |

Ø18 |

Ø22 |

Ø25 |

Ø32 |

Ø40 |

Ø45 |

|||

|

06 |

ISO 2-hole |

80 |

100 |

100 |

125 |

125 |

– |

A |

|

|

ISO 4-hole |

– |

– |

– |

– |

– |

180 |

B |

||

|

SAE 2-hole |

82,55 |

101,6 |

101,6 |

127 |

127 |

– |

C |

||

|

SAE 4-hole |

– |

– |

– |

– |

– |

152,4 |

D |

||

|

Port for working lines pressure port B and suction port S |

|||||||||

|

07 |

SAE, laterally opposite, mounting thread metric |

● |

● |

● |

● |

● |

● |

12 |

|

|

Through-drive (All through-drives with single pumps come without a hub and are operationally safe, provided with an end cover) |

|||||||||

|

08 |

Without through-drive |

● |

● |

● |

● |

● |

● |

N00 |

|

|

Centering |

Attachment pump (examples) 2) |

||||||||

|

ISO Ø100 mm |

A10VSO..31 NG28/45 |

– |

● |

● |

● |

● |

● |

KD3 |

|

|

ISO Ø125 mm |

A10VSO..31 NG71/100 |

– |

– |

– |

● |

● |

● |

KD5 |

|

|

ISO Ø180 mm |

A10VSO..31 NG140 |

– |

– |

– |

– |

– |

● |

KD7 |

|

|

SAE Ø82.55 mm |

A10VSO..31 NG18, PGF2, PGH2, PGH3, AZPF |

● |

● |

● |

● |

● |

● |

KC1 |

|

|

SAE Ø101.6 mm |

PGH4, 1PF2G3, PGF3 |

– |

● |

● |

● |

● |

● |

KC3 |

|

|

SAE Ø127 mm |

PGH5 |

– |

– |

– |

● |

● |

● |

KC5 |

|

|

SAE Ø152.4 mm |

A10VO140 |

– |

– |

– |

– |

– |

● |

KC6 |

|

|

Base pump variant |

|||||||||

|

09 |

Standard (internal pilot oil) |

● |

● |

● |

● |

● |

● |

● |

0000 |

|

External supply |

– |

● |

● |

● |

● |

● |

– |

0479 |

|

|

External supply + regenerative operation |

– |

– |

– |

– |

● |

● |

● |

0487 |

|

|

Pilot and preload valve of the SYDFE1 control system |

|||||||||

|

Spool design |

|||||||||

|

10 |

Standard (NG28 ... NG140) |

A |

|||||||

|

2-groove spool (NG18 ... NG140, only for replacement requirement) |

B |

||||||||

|

4-groove spool (NG18) |

C |

||||||||

|

Installation orientation, solenoid |

|||||||||

|

11 |

Mating connector is orientated radially to the pump axis |

0 |

|||||||

|

12 |

Features currently not used |

X0XX |

|||||||

|

Preload valve with integrated pressure limitation |

|||||||||

|

13 |

Pressure limitation 200 bar (tolerance ± 8 bar) |

1 |

|||||||

|

Pressure limitation 250 bar (tolerance ± 10 bar) |

2 |

||||||||

|

Pressure limitation 300 bar (tolerance ± 12 bar) |

3 |

||||||||

|

Without preload valve |

X |

||||||||

|

14 |

Further details in the plain text e. g. SO variant |

* |

|||||||

| 1) | ANSI B92.1a-1976, 30° pressure angle, flat root, side fit, tolerance class 5. |

| 2) | Also observe the conditions for the attachment pumps. |

|

● |

available |

|

- |

not available |

Ordering code pump combination SYHDFE1-2X

|

01 |

02 |

03 |

04 |

05 |

||||

|

SY2HDFE1-2X |

/ |

– |

/ |

+ |

|

01 |

2-fold pump |

SY2HDFE1-2X |

|

02 |

Size of the main pump 1) |

|

|

03 |

Size of the attachment pump or pump abbreviation if the attachment pump is not SYHDFE (e.g. PGF) 1) |

|

|

04 |

Material number without "R9" for the main pump or type designation if material number is not known |

|

|

05 |

Material number without "R9" for the attachment pump or type designation if material number is not known |

| 1) | Detailed information see type key |

|

01 |

02 |

03 |

04 |

|||

|

SY3HDFE1-2X |

/ |

+ |

+ |

|

01 |

3-fold pump |

SY3HDFE1-2X |

|

02 |

Material number without "R9" for the main pump or type designation if material number is not known |

|

|

03 |

Material number without "R9" for the attachment pump or type designation if material number is not known |

|

|

04 |

Material number without "R9" for the attachment pump or type designation if material number is not known |

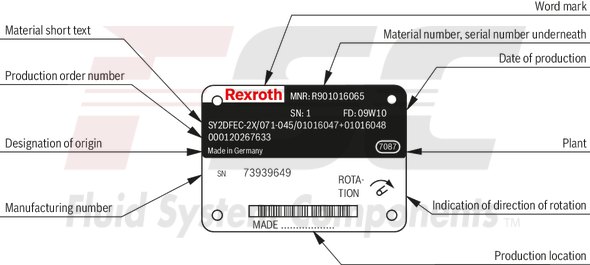

Example of name plate of a pump combination

For enquiries regarding the control system, material number, production order number, serial number, and date of production are necessary.

|

Accessories |

Material number |

Data sheet |

|

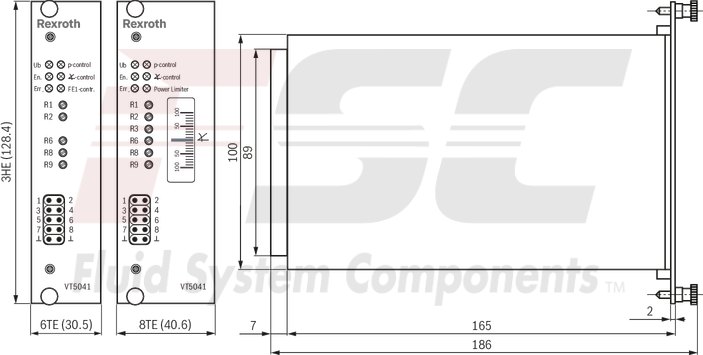

External control electronics VT 5041-3X/1 without power limitation, without swivel angle display |

R901236404 |

30242 |

|

External control electronics VT 5041-3X/2 without power limitation, with swivel angle display |

R901263598 |

30242 |

|

External control electronics VT 5041-3X/3 with power limitation, with swivel angle display |

R901196678 |

30242 |

|

Mating connector for solenoid plug |

R901017011 |

08006 |

|

Mating connector for position transducer of valve |

R900023126 |

08006 |

|

Mating connector for position transducer of pump |

R900013674 |

|

|

Pressure transducer HM 20-2X, measurement range 315 bar (4 ... 20 mA) |

R901342029 |

30272 |

|

Pressure transducer HM 20-2X, measurement range 315 bar (0.1 ... 10 V) |

R901342030 |

30272 |

|

Card holder VT 3002-1-2X/32D |

R900020153 |

29928 |

|

Compact power supply unit VT-NE32-1X |

R900080049 |

29929 |

|

More accessories |

||

|

Accessories for through-drives |

See Accessories |

|

|

Torsionally flexible couplings for attachment to a standard electric motor |

See Accessories |

|

mechanic and hydraulic

|

Size |

18 | 28 | 45 | 71 | 100 | 140 | ||||

|

Displacement |

Vg max |

cm³ |

18 | 28 | 45 | 71 | 100 | 140 | ||

|

Speed 1) |

maximum at Vg max |

nnom |

rpm |

3300 | 3000 | 2600 | 2200 | 2000 | 1800 | |

|

maximum at Vg < Vg max |

nmax zul |

rpm |

3900 | 3600 | 3100 | 2600 | 2400 | 2100 | ||

|

Minimum speed |

nmin |

rpm |

50 | |||||||

|

Max. flow (displacement) |

at nnom and Vg max |

qV max |

l/min |

59.4 | 84 | 117 | 156 | 200 | 252 | |

|

with nE = 1500 rpm and Vg max |

qvE max |

l/min |

27 | 42 | 68 | 107 | 150 | 210 | ||

|

Max. power (Δp = 280 bar) |

at nnom and Vg max |

P max |

kW |

27.7 | 39 | 55 | 73 | 93 | 118 | |

|

with nE = 1500 rpm and Vg max |

PE max |

kW |

12.6 | 20 | 32 | 50 | 70 | 98 | ||

|

Max. torque (Δp = 280 bar) |

Tmax |

Nm |

80.1 | 125 | 200 | 316 | 445 | 623 | ||

|

Maximum permissible drive torque |

Fitting key |

Ttotal |

Nm |

88 | 137 | 200 | 439 | 857 | 1206 | |

|

Splined shaft S overall torque |

Ttotal |

Nm |

124 | - | 1104 | 1620 | ||||

|

Max. admissible through-drive torque |

TD |

Nm |

108 | - | 778 | 1266 | ||||

|

Splined shaft R overall torque |

Ttotal |

Nm |

- | 225 | 400 | 644 | - | |||

|

Max. admissible through-drive torque |

TD |

Nm |

- | 176 | 365 | 548 | - | |||

|

Drive shaft load |

|

max. admissible axial force |

Fax max |

N |

700 | 1000 | 1500 | 2400 | 4000 | 4800 |

|

max. admissible radial force |

Fq |

N 2) |

350 | 1200 | 1500 | 1900 | 2300 | 2800 | ||

|

Mass |

Pump without through-drive incl. pilot valve |

m |

kg |

14 | 17 | 23 | 35 | 47 | 62 | |

|

in addition, preload valve |

m |

kg |

3.3 | 6.3 | ||||||

|

in addition, in case of external supply |

m |

kg |

2 | |||||||

|

Moment of inertia around drive axis |

kg·m² |

0.0009 | 0.0017 | 0.0033 | 0.0083 | 0.0167 | 0.0242 | |||

|

Filling quantity of the housing |

l |

0.4 | 0.7 | 1 | 1.6 | 2.2 | 3 | |||

|

Maximum admissible operating pressure |

pmax |

bar |

280 3) | 280 | ||||||

|

Operating pressure, min. (without load) |

with preload valve |

pmin |

bar |

≥ 1 | ||||||

|

without preload valve |

pmin |

bar |

≥ 20 | |||||||

|

in case of external supply (20 bar) 4) |

pmin |

bar |

> 10 | |||||||

|

Admissible inlet pressure |

p |

bar |

0.8 ... 10 | |||||||

|

Hydraulic fluid |

Mineral oil (HL, HLP) to DIN 51524 | |||||||||

|

Hydraulic fluid temperature range |

ϑ |

°C |

-20 … +70 | |||||||

|

Maximum admissible degree of contamination of the hydraulic fluid according to ISO 4406 |

Class 18/16/13 (for particle size ≤ 4/6/14 μm) | |||||||||

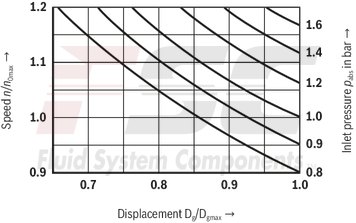

| 1) | The values are applicable at an absolute pressure of 1 bar at the suction opening S. With a reduction of the displacement or an increase in the inlet pressure, the speed can be increased according to the following characteristic curve. With a reduced inlet pressure, the speed is to be reduced. |

| 2) | In case of higher radial forces, please consult us |

| 3) | In case of higher pressures, please consult us |

| 4) | In continuous operation; in case of operation below 10 bar, observe the notes |

Notice:

For information on the environment simulation testing for the areas of EMC (electro-magnetic compatibility), climate and mechanical load, see data sheet 30030-U.

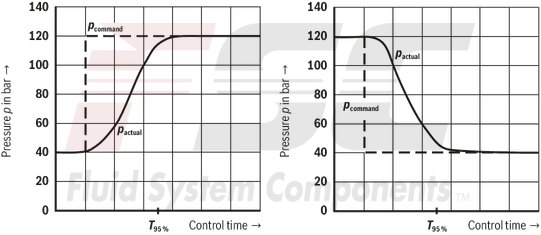

Control loop quality

Notes:

The specified values are only valid when using the system-related components specified in this data sheet. At pressures < 20 bar, higher tolerances have to be anticipated due to lower actuating forces.|

Swivel angle control |

Pressure control 1) |

|

|

Linearity tolerance |

≤ 1.0 % |

≤ 1.5 % (≤ 1.0 %) |

|

Temperature error |

≤ 0.5 % / 10 K |

≤ 0.5 % / 10 K |

|

Hysteresis |

≤ 0.2 % |

≤ 0.2 % |

|

Repetition accuracy |

≤ 0.2 % |

≤ 0.2 % |

| 1) | Without considering the pump pulsation. |

For applications outside these parameters, please consult us!

Transition function with pressure command value step with spool design "A"

The specified curve shapes and control times refer to a drive speed of 1500 rpm and are only reached with an optimization of the pressure controller.

T 95% in ms with a connected hydraulic fluid volume (lines and actuators)

|

Hydraulic fluid volume in l |

T95% in ms |

|

< 5 |

150 |

|

5 ... 10 |

200 |

|

15 ... 15 |

250 |

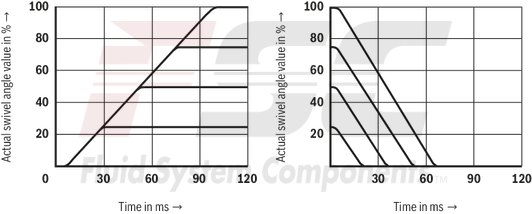

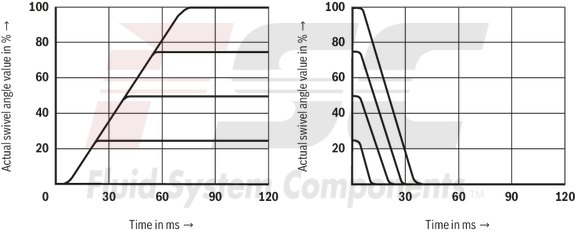

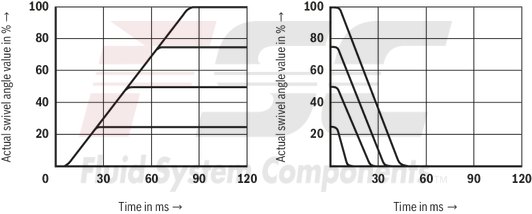

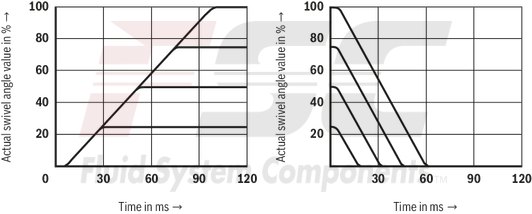

Transition function with swivel angle command value step with spool design "A"

Size 18, 28, 45, 71 p = 20 bar

Size 18, 28, 45, 71 p = 50 bar

Size 100 p = 50 bar

Size 140 p = 50 bar

For pressures up to 40 bar, the values of the response times are greater.

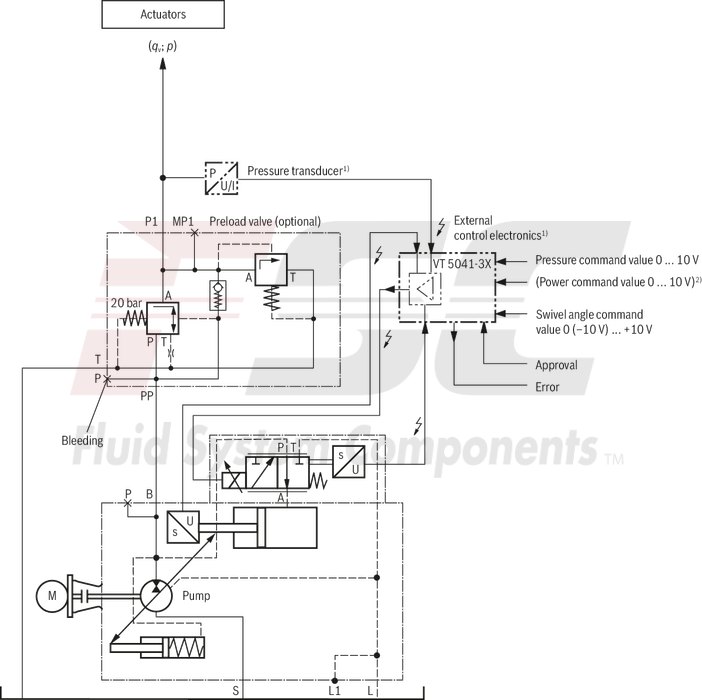

Schematic diagram: Actuating system supplied internally

| 1) | Separate order |

| 2) | Optional |

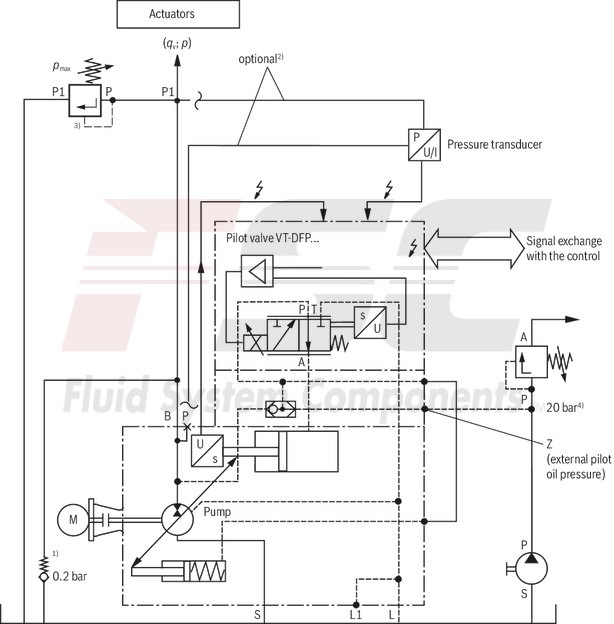

Schematic diagram: Actuating system supplied externally

The representation shows an example with integrated electronics. The external supply of the actuating system is also possible with external electronics.

| 1) | The use of an anti-cavitation valve (check valve with 0.2 bar spring) is essential in order to prevent dry-running in the error case. |

|

2) |

Pressure transducer |

Mounting options |

Comment |

|

HM 20-2X/315-F-C13-0.5 (cable version) |

P |

Only in connection with actual pressure value input "F" |

|

|

HM 20-2X/...-.-K35 (connector version) |

P1 |

Preferably close to the actuator |

| 3) Maximum pressure limitation must be provided by the customer! | |

| 4) Observe upper limit for external pilot oil pressure! (see operating instructions), recommendation: 20 bar absolute. |

Important notes on external supply:

In the case of an actuating system with external supply, the pump adjustment will - in case of voltage failure - not switch to zero stroke but to the negative stop (displacement of 100 % flow from the system to the tank). With an active fault message, it is imperative that the machine control reacts (e. g. switching off the drive motor of the pump, interrupting the external supply of the actuating system). The command values for pressure and flow must always be greater than zero (pcommand ≥ 3 bar, αcommand ≥ 5 %) as due to drift or tolerances, there is no exact "zero" pressure or "zero" swivel angle. Under unfavorable conditions, smaller command value presettings can lead to cavitation. The actual pressure value must not be less than 10 bar for more than 10 minutes (lubrication).

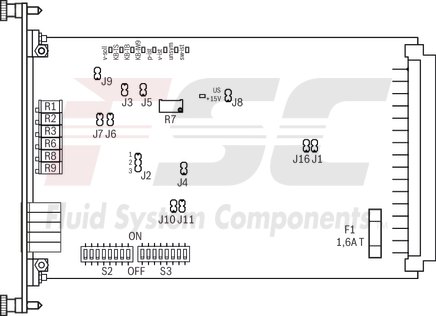

|

Leakage compensation |

Jumper |

|

|

J6 |

J7 |

|

|

Off |

OFF |

OFF |

|

4 % |

OFF |

ON |

|

6 % |

ON |

OFF |

|

10 % |

ON |

ON |

|

Valve command value monitoring |

Jumper |

|

J9 |

|

|

On |

ON |

|

Off * |

OFF |

|

Diagnosis LEDs |

|

For a description, see block diagram and the operating instructions 30011-B |

|

Regenerative operation |

Jumper |

|

|

J3 |

J5 |

|

|

On |

ON |

OFF |

|

Off |

OFF |

ON |

|

Function pin 18a ** |

Jumper |

|

J4 |

|

|

Pressure control |

OFF |

|

Master/slave |

ON |

|

** Only for versions without power limitation (VT 5041-3X/1-0 and VT 5041-3X/2-0) |

|

|

Selection for analog input at pin 18c |

Jumper |

|

J2 |

|

|

Bridge |

|

|

Actual master swivel angle value |

1-2 |

|

external power limitation |

2-3 |

|

Pressure controller p amplification |

Switch S3 |

Jumper |

|

|

.7 |

.8 |

J11 |

|

|

8,0 |

OFF |

OFF |

OFF |

|

4,8 |

OFF |

ON |

OFF |

|

4,0 |

OFF |

OFF |

ON |

|

3,0 |

OFF |

ON |

ON |

|

2,4 |

ON |

OFF |

ON |

|

2,0 |

ON |

ON |

ON |

|

Volume adjustment of pressure controller |

|||

|

Input switch TD = OFF |

Switch S3 |

||

|

.1 |

.2 |

.3 |

|

|

≤ 5,0 l |

OFF |

OFF |

OFF |

|

7,5 l |

OFF |

ON |

OFF |

|

10,0 l |

ON |

ON |

OFF |

|

15,0 l |

ON |

OFF |

ON |

|

20,0 l |

OFF |

ON |

ON |

|

25,0 l |

ON |

ON |

ON |

|

Input switch TD = ON |

Switch S3 |

||

|

.4 |

.5 |

.6 |

|

|

12,5 l |

OFF |

OFF |

OFF |

|

30,0 l |

OFF |

ON |

OFF |

|

45 l |

ON |

ON |

OFF |

|

60 l |

ON |

OFF |

ON |

|

75 l |

OFF |

ON |

ON |

|

90 l |

ON |

ON |

ON |

|

Actual pressure value amplification |

Jumper |

|

J10 |

|

|

1-fold |

OFF |

|

2-fold |

ON |

|

Signal adjustment of actual pressure value |

Switch S2 |

||||||||

|

.1 |

.2 |

.3 |

.4 |

.5 |

.6 |

.7 |

.8 |

||

|

V |

0...10 V |

OFF |

OFF |

OFF |

OFF |

OFF |

OFF |

ON |

ON |

|

E |

1...10 V |

OFF |

OFF |

OFF |

OFF |

ON |

OFF |

OFF |

ON |

|

D |

0...5 V |

OFF |

OFF |

ON |

ON |

OFF |

OFF |

ON |

ON |

|

F |

0,5...5 V |

OFF |

OFF |

ON |

ON |

ON |

OFF |

OFF |

ON |

|

B |

0...20 mA |

ON |

ON |

OFF |

OFF |

OFF |

OFF |

ON |

ON |

|

C |

4...20 mA |

ON |

ON |

OFF |

OFF |

ON |

ON |

OFF |

OFF |

|

Explanations: |

|

|

ON |

Bridge closed |

|

OFF |

Bridge open |

|

Factory setting |

|

For the meaning of the measuring sockets, display and adjustment elements (potentiometer) on the front plate, see front plate.

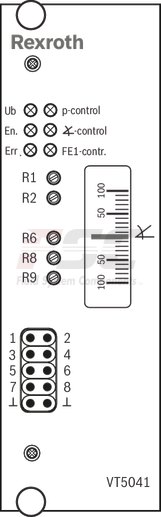

VT 5041-3X/1-0

|

LED displays |

|

|

Ub (green) |

Supply voltage available |

|

En. (green) |

Enable available |

|

Err. (red) |

Fault/collective error |

|

p-control (yellow) |

Pressure control enabled |

|

Swivel angle control enabled |

|

|

FE1 contr. (yellow) |

Pressure controller disabled |

|

Adjustment elements (potentiometer) |

|

|

R1 |

Zero point of actual pressure value |

|

R2 |

Actual pressure value amplification |

|

R6 |

Zero point of actual valve value |

|

R8 |

Zero point of actual swivel angle value |

|

R9 |

Amplification of actual swivel angle value |

|

Measuring sockets (Ri = 2 kΩ) |

|

|

1 |

Pressure command value 0…+10 V |

|

2 |

Actual pressure value 0…+10 V |

|

3 |

Swivel angle command value ±10 V |

|

4 |

Swivel angle command value |

|

5 |

Valve command value ±10 V |

|

6 |

Actual valve value ±10 V |

|

7 |

Active swivel angle command value ±10 V |

|

8 |

Power limit 0…+10 V |

|

⊥ |

Reference for measured values |

|

⊥ |

Reference for measured values |

|

Display (measuring instrument) |

|

|

Display of actual swivel angle value in % |

|

VT 5041-3X/2-0

|

LED displays |

|

|

Ub (green) |

Supply voltage available |

|

En. (green) |

Enable available |

|

Err. (red) |

Fault/collective error |

|

p-control (yellow) |

Pressure control enabled |

|

Swivel angle control enabled |

|

|

FE1 contr. (yellow) |

Pressure controller disabled |

|

Adjustment elements (potentiometer) |

|

|

R1 |

Zero point of actual pressure value |

|

R2 |

Actual pressure value amplification |

|

R6 |

Zero point of actual valve value |

|

R8 |

Zero point of actual swivel angle value |

|

R9 |

Amplification of actual swivel angle value |

|

Measuring sockets (Ri = 2 kΩ) |

|

|

1 |

Pressure command value 0…+10 V |

|

2 |

Actual pressure value 0…+10 V |

|

3 |

Swivel angle command value ±10 V |

|

4 |

Swivel angle command value |

|

5 |

Valve command value ±10 V |

|

6 |

Actual valve value ±10 V |

|

7 |

Active swivel angle command value ±10 V |

|

8 |

Power limit 0…+10 V |

|

⊥ |

Reference for measured values |

|

⊥ |

Reference for measured values |

|

Display (measuring instrument) |

|

|

Display of actual swivel angle value in % |

|

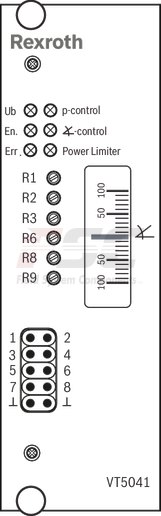

VT 5041-3X/3-0

|

LED displays |

|

|

Ub (green) |

Supply voltage available |

|

En. (green) |

Enable available |

|

Err. (red) |

Fault/collective error |

|

p-control (yellow) |

Pressure control enabled |

|

Swivel angle control enabled |

|

|

Power Limiter (yellow) |

Power limitation active |

|

Adjustment elements (potentiometer) |

|

|

R1 |

Zero point of actual pressure value |

|

R2 |

Actual pressure value amplification |

|

R3 |

Setting of the power limit |

|

R6 |

Zero point of actual valve value |

|

R8 |

Zero point of actual swivel angle value |

|

R9 |

Amplification of actual swivel angle value |

|

Measuring sockets (Ri = 2 kΩ) |

|

|

1 |

Pressure command value 0…+10 V |

|

2 |

Actual pressure value 0…+10 V |

|

3 |

Swivel angle command value ±10 V |

|

4 |

Swivel angle command value |

|

5 |

Valve command value ±10 V |

|

6 |

Actual valve value ±10 V |

|

7 |

Active swivel angle command value ±10 V |

|

8 |

Power limit 0…+10 V |

|

⊥ |

Reference for measured values |

|

⊥ |

Reference for measured values |

|

Display (measuring instrument) |

|

|

Display of actual swivel angle value in % |

|

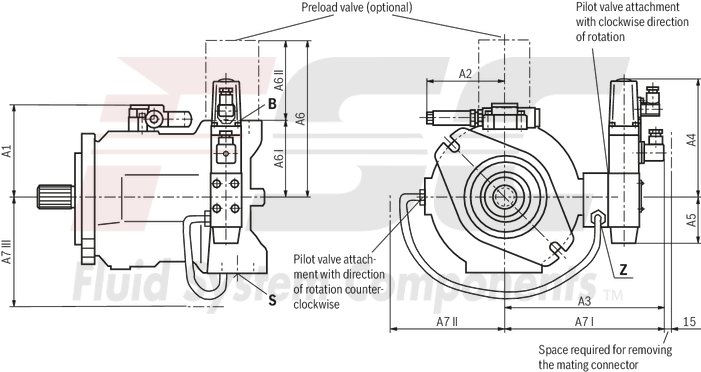

Electrical properties of the SYDFE1 see VT 5041

The unit dimensions of the base pump (axial piston variable displacement pump A10VSO.../31) are contained in data sheet 92711.

Size 18 … 140

(Shaft design "S”; without through-drive “N00”)

Dimensions in mm

(representation Size 71)

|

Dimensions with base pump variant "0479" or "0487" |

|||||||||||

|

Size |

A1 |

A2 |

A3 |

A4 |

A5 |

A6 |

A6 I |

A6 II |

A7 I |

A7 II |

A7 III |

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

| 18 | 98 | 110 | 161 | 158 | 63 | 178 | 63 | 115 | 196 | 125 | 100 |

| 28 | 106 | 110 | 171 | 158 | 63 | 195 | 80 | 115 | 206 | 135 | 115 |

| 45 | 112 | 110 | 181 | 158 | 63 | 205 | 90 | 115 | 216 | 145 | 125 |

| 71 | 124 | 110 | 195 | 158 | 63 | 254 | 104 | 150 | 230 | 159 | 150 |

| 100 | 129 | 110 | 200 | 158 | 63 | 247 | 100 | 147 | 235 | 164 | 150 |

| 140 | 140 | 110 | 213 | 143 | 78 | 257 | 110 | 147 | 248 | 182 | 150 |

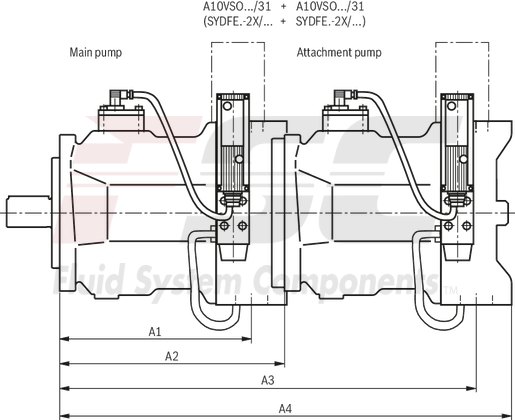

Combination pumps

|

Attachment pump |

Main pump |

|||||||||||||||||||||||

|

A10VSO 18 |

A10VSO 28 |

A10VSO 45 |

A10VSO 71 |

A10VSO 100 |

A10VSO 140 |

|||||||||||||||||||

|

A1 |

A2 |

A3 |

A4 |

A1 |

A2 |

A3 |

A4 |

A1 |

A2 |

A3 |

A4 |

A1 |

A2 |

A3 |

A4 |

A1 |

A2 |

A3 |

A4 |

A1 |

A2 |

A3 |

A4 |

|

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

|

A10VSO 18 |

164 |

204 |

349 |

399 |

164 |

204 |

349 |

399 |

184 |

229 |

374 |

424 |

217 |

267 |

412 |

462 |

275 |

338 |

483 |

533 |

275 |

350 |

495 |

554 |

|

A10VSO 28 |

164 |

204 |

368.5 |

410 |

184 |

229 |

393.5 |

435 |

217 |

267 |

431.5 |

473 |

275 |

338 |

502.5 |

544 |

275 |

350 |

514 |

556 |

||||

|

A10VSO 45 |

184 |

229 |

413 |

453 |

217 |

267 |

451 |

491 |

275 |

338 |

522 |

562 |

275 |

350 |

534 |

574 |

||||||||

|

A10VSO 71 |

217 |

267 |

484 |

524 |

275 |

338 |

555 |

595 |

275 |

350 |

567 |

609 |

||||||||||||

|

A10VSO 100 |

275 |

338 |

613 |

664 |

275 |

350 |

625 |

679 |

||||||||||||||||

|

A10VSO 140 |

275 |

350 |

625 |

688 |

||||||||||||||||||||

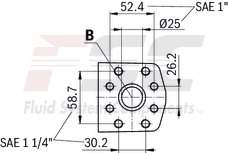

Ports

|

Size |

18 |

28 |

45 |

71 |

100 |

140 |

||

|

B: |

Working line (SAE J518) 1) |

|||||||

|

Size |

3/4" |

3/4" |

1" |

1" |

1 1/4" |

1 1/4" |

||

|

Mounting thread (DIN 13) |

M10 x 1.5; 17 deep |

M14 x 2; 19 deep |

||||||

|

Maximum pressure 2) |

bar |

350 |

||||||

|

S: |

Suction line (SAE J518) 1) |

|||||||

|

Size |

1" |

1 1/4" |

1 1/2" |

2" |

2 1/2" |

2 1/2" |

||

|

Mounting thread (DIN 13) |

M10 x 1.5; 17 deep |

M12 x 1.75; 20 deep |

M12 x 1.75; 17 deep |

|||||

|

Maximum pressure 2) |

bar |

10 |

||||||

| 1) | Dimensions according to SAE J518 only, metric mounting thread deviating from the standard. |

| 2) | Application-specific short-time pressure peaks may occur. Please observe when selecting measuring devices and fittings. Specified pressures are in bar absolute. |

Notes regarding size 71:

With pressure connection “B” of size 71, two SAE mounting connections rotated by 90° are available. SAE 1 1/4″ standard pressure series, 207 bar , for pressures up to 250 bar or SAE 1″ standard pressure series, 344 bar, for pressures up to 350 bar. For operating pressures exceeding 250 bar, the pressure flange SAE 1” must be used.Dimensions in mm

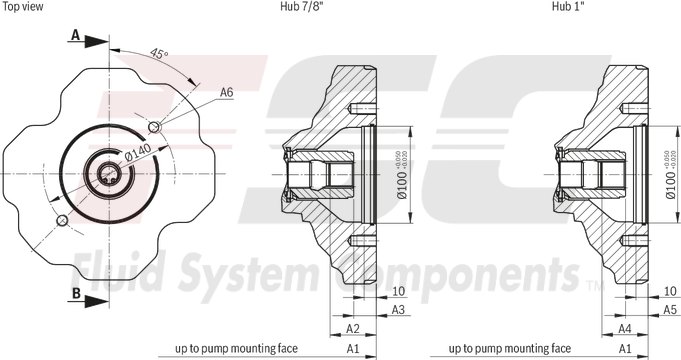

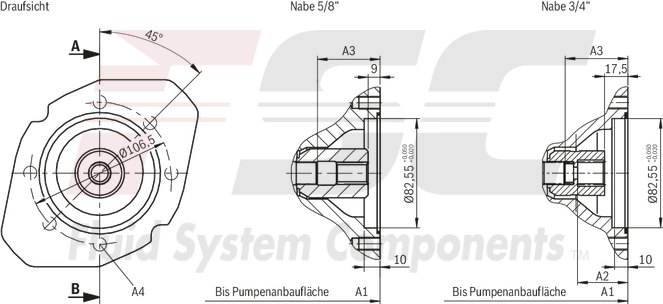

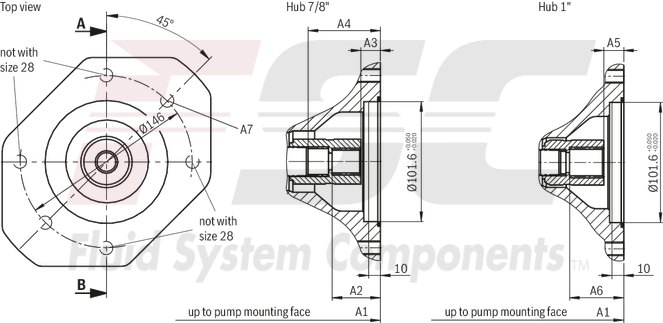

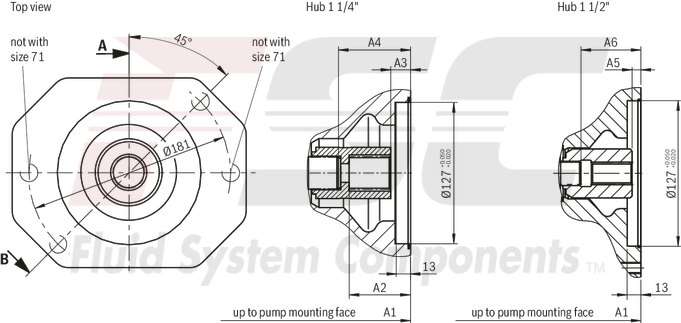

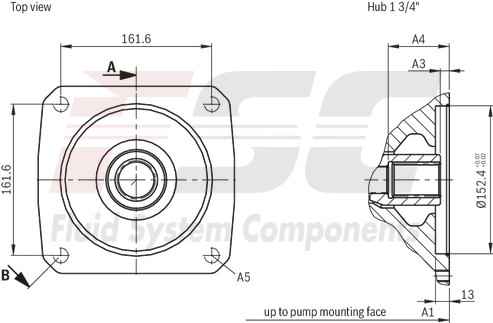

Hubs for through-drives

Hubs for the combination of single pumps or the combination of SYDFE with other pumps. Observe that the attachment pump has a splined shaft SAE J744 with the specified diameter.

The following conditions apply to the attachment pumps listed in the table:

SYDFE and A10VSO with shaft S or R Internal gear pump PGH with shaft R, flange U2, see data sheet 10223 Internal gear pump PGF3 with shaft J, flange U2, see data sheet 10213 External gear pump AZPF with shaft R, front cover R, see data sheet 10089Observe that the through-drive of the main pump and the flange of the attachment pump (see type key pump) are identical. Check in the current data sheet of the gear pump whether the shaft ends have the specified dimensions.

|

Main pump SYDFE or A10VSO... |

Attachment pump |

||||||

|

Size 18 |

Size 28 |

Size 45 |

Size 71 |

Size 100 |

Size 140 |

Ø shaft |

Pump type (examples) |

|

R902436099 |

R902436199 |

R902436100 |

R902436200 |

R902436201 |

R902436202 |

3/4" 19-4 (SAE A-B) |

SYDFE-2X, A10VSO..31 |

|

R902436098 |

R902436084 |

R902436083 |

R902436101 |

R902436102 |

7/8" 22-4 (SAE B) |

SYDFE-2X, A10VSO..31 |

|

|

R902436103 |

R902436104 |

R902436105 |

R902436204 |

1" 25-4 (SAE B-B) |

SYDFE-2X, A10VSO..31 |

||

|

R902436085 |

R902436105 |

R902436106 |

1 1/4" 32-4 (SAE C) |

SYDFE-2X, A10VSO..31 |

|||

|

R902436086 |

R910943555 |

1 1/2" 38-4 (SAE C-C) |

SYDFE-2X, A10VSO..31 |

||||

|

R910943565 |

R910932172 |

1 3/4" 44-4 (SAE D) |

SYDFE-2X, A10VSO..31 |

||||

|

R910943528 |

R910986299 |

R910943529 |

R91094345 |

R910943560 |

R910943551 |

5/8" 16-4 (SAE A) |

1PF2G2, PGF2, PGH2, PGH3, AZPF |

Through-drives

KD3

Flange ISO 100, 2-hole for the attachment of

SYDFE.-2X (size 28 and size 45, flange A) A10VSO..31 (size 28 and size 45, flange A, see data sheet 92711)

Sectional presentation with examples for hubs (order number for hubs see hubs for through-drives)

Dimensions in mm

|

Size |

A1 |

A2 |

A3 |

A4 |

A5 |

A6 |

|

mm |

mm |

mm |

mm |

mm |

||

| 28 | 204 | 41.7 | 17.8 | - | - | M12; 15 right through |

| 45 | 229 | 41.7 | 17.9 | 46.7 | 18.4 | M12; 14 right through |

| 71 | 267 | 44.1 | 20.3 | 49.1 | 20.8 | M12; 20 deep |

| 100 | 338 | 41 | 17.6 | 45.9 | 18.2 | M12; 20 deep |

| 140 | 350 | 41.1 | 18 | 45.9 | 18.3 | M12; 20 deep |

KD5

Flange ISO 125, 2-hole for the attachment of

SYDFE.-2X (size 71 and size 100, flange A) A10VSO..31 (size 71 and size 100, flange A, see data sheet 92711)

Sectional presentation with examples for hubs (order number for hubs see hubs for through-drives)

Dimensions in mm

|

Size |

A1 |

A2 |

A3 |

A4 |

A5 |

A6 |

|

mm |

mm |

mm |

mm |

mm |

||

| 71 | 267 | 58.6 | 21.8 | - | - | M16; 20 right through |

| 100 | 338 | 56.4 | 19.5 | 63.9 | 7.9 | M16; 20 deep |

| 140 | 350 | 55.4 | 17.4 | 73.3 | 7.9 | M16; 20 deep |

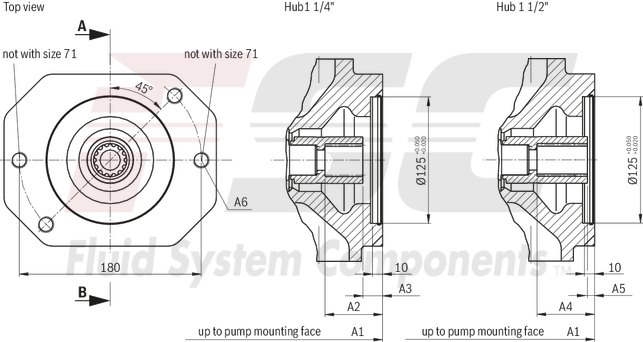

KD7

Flange ISO 180, 4-hole for the attachment of

SYDFE.-2X (NG140, flange B) A10VSO..31 (NG140, flange B, see data sheet 92711)

Sectional presentation with examples for hubs (order number for hubs see hubs for through-drives)

Dimensions in mm

|

Size |

A1 |

A2 |

A3 |

A5 |

|

mm |

mm |

mm |

||

| 140 | 350 | 75 | 8 | M16; 22 right through |

KC1

Flange SAE 82-2 (SAE A, 2-hole) for the attachment of

SYDFE.-2X (size 18, flange C) A10VSO..31 (size 18, flange C, see data sheet 92711) PGF2 (shaft J, flange U2, see data sheet 10213) PGH2 and PGH3 (shaft R, flange U2, see data sheet 10223) AZPF (shaft R, front cover R, see data sheet 10089)

Sectional presentation with examples for hubs (order number for hubs see hubs for through-drives)

Dimensions in mm

|

Size |

A1 |

A2 |

A3 |

A4 |

|

mm |

mm |

mm |

||

| 18 | 182 | 40 | 43 | M10; 14.5 deep |

| 28 | 204 | 39 | 47 | M10; 16 deep |

| 45 | 229 | 40.5 | 53 | M10; 16 deep |

| 71 | 267 | 40 | 61 | M10; 20 deep |

| 100 | 338 | 40 | 65 | M10; 20 deep |

| 140 | 350 | 41 | 77 | M10; 17 deep |

KC3

Flange SAE 101-2 (SAE B, 2-hole) for the attachment of

SYDFE.-2X (size 28 and size 45, flange C) A10VO..31 (size 28 and size 45, flange C, see data sheet 92701) PGF3 (shaft J, flange U2, see data sheet 10213) PGH4 (shaft R, flange U2, see data sheet 10223)

Sectional presentation with examples for hubs (order number for hubs see hubs for through-drives)

Dimensions in mm

|

Size |

A1 |

A2 |

A3 |

A4 |

A5 |

A6 |

A7 |

|

mm |

mm |

mm |

mm |

mm |

mm |

||

| 28 | 204 | 43 | 16.5 | 47 | - | - | M12; 15 deep |

| 45 | 229 | 42 | 16.5 | 53 | 18.4 | 46.7 | M12; 18 deep |

| 71 | 267 | 43 | 16.5 | 61 | 20.8 | 49.1 | M12; 20 deep |

| 100 | 338 | 41 | 16.5 | 65 | 10.5 | 65 | M12; 20 deep |

| 140 | 350 | 44 | 16.5 | 77 | 18.3 | 45.9 | M12; 20 deep |

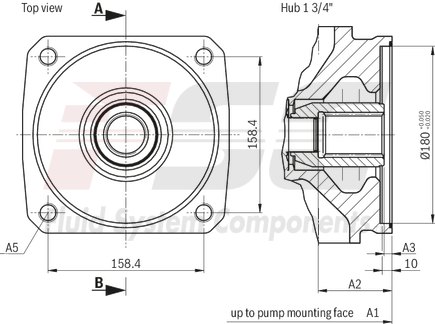

KC5

Flange SAE 127-2 (SAE C, 2-hole) for the attachment of

SYDFE.-2X (size 71 and size 100, flange C) A10VO..31 (size 71 and size 100, flange C, see data sheet 92701) PGH5 (shaft R, flange U2, see data sheet 10223)

Sectional presentation with examples for hubs (order number for hubs see hubs for through-drives)

Dimensions in mm

|

Size |

A1 |

A2 |

A3 |

A4 |

A5 |

A6 |

A7 |

|

mm |

mm |

mm |

mm |

mm |

mm |

||

| 71 | 267 | 55.5 | 17.9 | 61 | - | - | M16; 18 deep |

| 100 | 338 | 57 | 17.9 | 65 | 8 | 65 | M16; 25 deep |

| 140 | 350 | 60 | 17.9 | 77 | 9 | 77.3 | M16; 32 deep |

KC6

Flange SAE 152-4 (SAE D, 4-hole) for the attachment of

SYDFE.-2X (size 140, flange D) A10VO..31 (size 140, flange D, see data sheet 92701)

Sectional presentation with examples for hubs (order number for hubs see hubs for through-drives)

Dimensions in mm

|

Size |

A1 |

A3 |

A4 |

A5 |

|

mm |

mm |

mm |

||

| 140 | 350 | 10.5 | 77 | M16; 24 deep |

Dimensions in mm

Project planning information

Always shield command and actual value cables. The distance to aerial lines or radios must be at least 1 m. Do not lay signal lines close to power lines. For amending notes on the SYDFE control system, see the operating instructions (see section "More information about this control system").Torsionally flexible couplings for attachment to a standard electric motor

|

Motor |

SYDFE.-2X |

|||

|

Frame size/characteristic |

Shaft diameter |

NG18 Shaft S, 3/4” |

NG28 Shaft S or R, 7/8″ |

NG45 Shaft S or R, 1″ |

|

100/0 112/0 |

28 |

R901038012 |

R901038017 |

|

|

132/0 |

38 |

R900704699 |

R901012344 |

R900772898 |

|

160/0 |

42 |

R900726977 |

R900991864 |

R900994283 |

|

180/0 |

48 |

R900032918 |

R900062159 |

|

|

200/0 |

55 |

R901038026 |

R901038025 |

|

|

225/0 |

60 |

R900750847 |

R901066409 |

|

|

250/0 |

65 |

R900988348 |

||

|

Motor |

SYDFE.-2X |

|||

|

Frame size/characteristic |

Shaft diameter |

NG71 Shaft S or R, 1 1/4" |

NG100 Shaft S, 1 1/2" |

NG140 Shaft S, 1 3/4" |

|

160/0 |

42 |

R900228413 |

||

|

180/0 |

48 |

R900240468 |

R900242567 |

|

|

200/0 |

55 |

R901038021 |

R901104689 |

R901038048 |

|

225/0 |

60 |

R900228375 |

R901050508 |

R900988121 |

|

250/0 |

65 |

R900986404 |

R901046864 |

R900708084 |

|

280/0 |

75 |

R900218487 |

R901055216 |

R901052451 |

|

315/0 |

80 |

R9010468941) |

R9010468301) |

|

|

315/1 |

80 |

R901046885 |

||

| 1) | Up to 40 °C |

Accessories

Version 12/2014, enquire availability

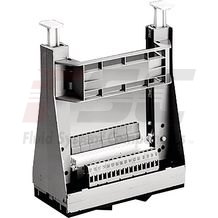

Card holder

VT 3002-2X

Card holder

VT 3002-2X

Component series 2XData sheet

Configurator / CAD

Spare parts & repair

External control electronics for the SYDFE1 control of the A10VSO axial piston variable displacement pump

VT 5041

External control electronics for the SYDFE1 control of the A10VSO axial piston variable displacement pump

VT 5041

Version Analog, Euro-card formatData sheet

Spare parts & repair