HYDRAFORCE

5026967

$218.00 USD

- HYDRAFORCE

- Material:5026967

- Model:HSPEC10-34-0-U-12ER SOLENOID VALVE

- Summary:SOLENOID PROPORTIONAL FLOW CONTROL VALVE, POPPET, NORMALLY CLOSED, PRESSURE COMPENSATED

Due to extremely high demand, please call 920-337-0234 for availability

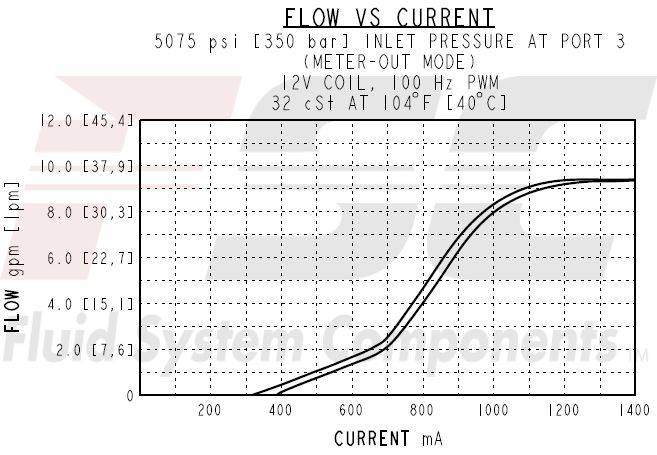

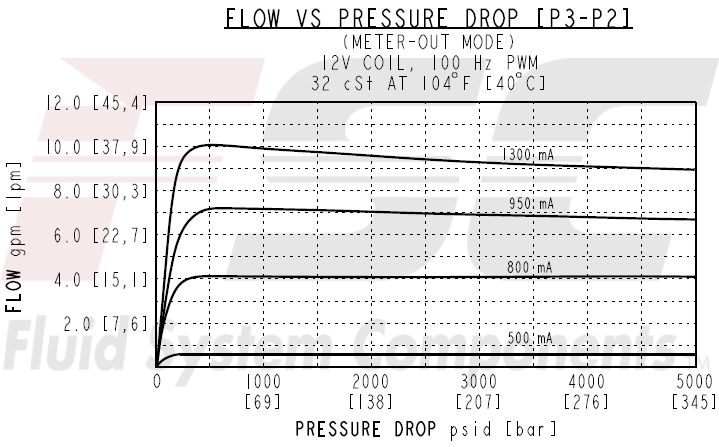

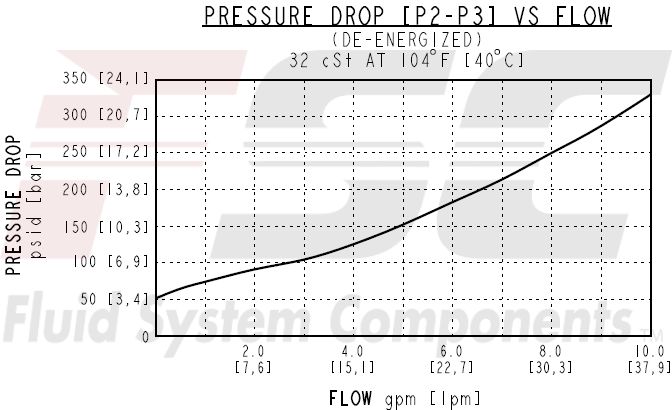

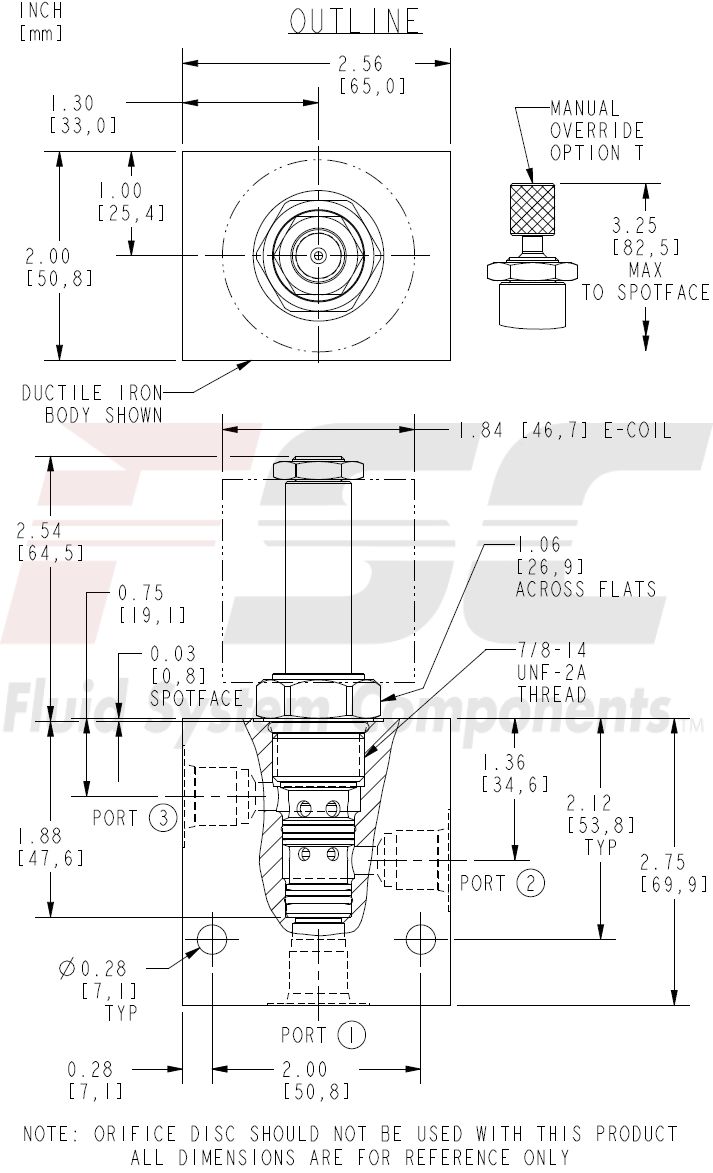

The Hydraforce 5026967 (5026967) is a sophisticated hydraulic cartridge valve designed for high-pressure applications requiring precise control over flow and pressure. This valve, known as the HSPEC1034X, operates as a proportional solenoid-operated, poppet type, restrictive type, pressure-compensated, normally closed flow control valve. It features built-in damping and load-holding capabilities which enhance its performance in various hydraulic systems. The operation of the HSPEC1034X is straightforward yet highly effective. When inlet at port 3 is activated, the valve regulates the flow exiting from port 2 independently of the load pressure. The flow rate is proportional to the current applied to its solenoid. For proper functionality, port 1 must be connected to port 3 to enable the load sense function of the compensator. In its default state when de-energized, this valve blocks flow from port 3 to port 2 while allowing free flow in the opposite direction. Noteworthy features of this model include an industry-common cavity that simplifies installation and integration into existing systems, continuous-duty rated coils that ensure reliable operation under sustained use, and an efficient wet-armature construction that minimizes space requirements in manifold setups. Additionally, it offers optional waterproof E-Coils rated up to IP69K for enhanced durability against harsh environmental conditions. The HSPEC1034X also boasts a patented high-strength solenoid tube for increased robustness. This Hydraforce valve adheres to stringent industry standards including NFPA specification T2.6.1, ensuring a verification level of 90% and an assurance level of 99%. This makes it a reliable component for advanced hydraulic systems where precision and durability are critical.

Unit weight:

0.19 kg (0.43 lb)

HSPEC10-34 without coil and nut

0.20 kg (0.45 lb)

HSPEC10-34T without coil and nut

Internal wetted surface area:

186.8 cm² (28.95 in²)

HSPEC10-34

191.2 cm² (29.64 in²)

HSPEC10-34T

| Ratings | Pressure Ratings Pressure rating: 350 bar (5075 psi) 420 bar (6090 psi) 10% cycle life Proof pressure: 690 bar (10000 psi) Burst pressure: 1380 bar (20000 psi) Flow Ratings Flow rating: 34 lpm (9 gpm) Maximum internal leakage: 7 drops/min With 350 bar (5075 psi) at port 3 Hysteresis: 5.7 lpm (1.50 gpm) Maximum Temperature Ratings Operating fluid temperature: -40 to 100 °C (-40 to 212 °F) With buna N seals -26 to 204 °C (-15 to 400 °F) With fluorocarbon seals -54 to 107 °C (-65 to 225 °F) With urethane seals Storage temperature: -40 to 70 °C (-40 to 160 °F) Ambient temperature: -40 to 70 °C (-40 to 160 °F) |

| Operating Parameters | Fluids:

Mineral based or synthetic hydraulic fluid with lubricating properties Fluid viscosity range: 7.4 to 420 cSt Maximum operating contamination level: 18/16/13 per ISO 4406 |

| Electrical Parameters | Note:

With size 10 E-series coil Maximum control current: 1300 mA Coil 12 V 650 mA Coil 24 V Threshold current: 300 to 500 mA 12 V coil 150 to 250 mA 24 V coil Dither PWM frequency: 100 to 200 Hz |

| Performance |    |

| Installation Specifications | Cavity:

HVC10-3 10-size 3-way Cavities Cartridge installation torque: 102 to 115 N-m (75 to 85 ft-lb) Steel/ductile iron cavity 81 to 88 N-m (60 to 65 ft-lb) Aluminum cavity Coil nut torque: 7 to 10 N-m (5 to 7 ft-lb) Orientation restriction: None |

| Order Code | POSITION CODE DESCRIPTION HSPEC10-34E-H-J-L E Manual Override E BLANK NONE E T Variable Position Override, Red Knurled Knob H Line Body H 0 No Body H 8HT Ductile iron SAE 8 J Seal J N Buna-N J V Fluorocarbon J U PPDI Urethane L Coil L 0 No Coil L 10EL 10 VDC, E-Coil, Dual Lead Wires L 10ER 10 VDC, E-Coil, Deutsch L 12EG 12 VDC, E-Coil, DIN 43650 L 12EJ 12 VDC, E-Coil, AMP Jr. L 12EL 12 VDC, E-Coil, Dual Lead Wires, 18 inches long L 12EL/36 12 VDC, E-Coil, Dual Lead Wires, 36 inches long L 12ER 12 VDC, E-Coil, Deutsch L 12EY 12 VDC, E-Coil, Metri-Pack 150 L 20ER 20 VDC, E-Coil, Deutsch L 24EG 24 VDC, E-Coil, DIN 43650 L 24EJ 24 VDC, E-Coil, AMP Jr. L 24EL 24 VDC, E-Coil, Dual Lead Wires, 18 inches long L 24EL/36 24 VDC, E-Coil, Dual Lead Wires, 36 inches long L 24ER 24 VDC, E-Coil, Deutsch L 24EY 24 VDC, E-Coil, Metri-Pack 150 |

Seal kit:

HSK10-3N-TB

Buna N

SK10-3V-TB

Fluorocarbon

SK10-3U-OO

Urethane

Seal kit installation instructions

Housings:

Available

10-3w valve bodies

Coils:

10 size E

coils

| Product PDF File | Download Product PDF File |