HYDRAFORCE

5610504

$50.25 USD

- HYDRAFORCE

- Material:5610504

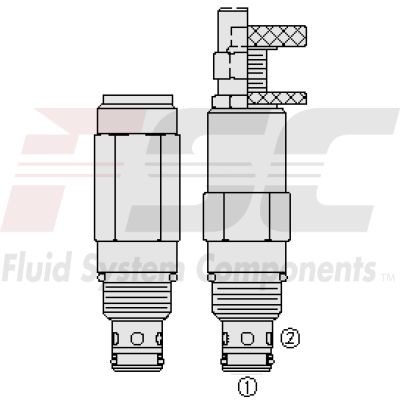

- Model:RV10-20L-0-N-33/ RELIEF VALVE

- Summary:RELIEF VALVE CARTRIDGE DIRECT ACTING POPPET

Due to extremely high demand, please call 920-337-0234 for availability

The Hydraforce 5610504 (5610504) is a screw-in, cartridge-style, direct-acting, poppet-type hydraulic relief valve designed to serve as a pressure limiting device for standard hydraulic circuit protection. It is compatible with mineral-based or synthetic hydraulic fluids that possess lubricating properties. The RV10-20X model effectively blocks flow from port 1 to port 2 until the pressure at port 1 reaches a level sufficient to displace the poppet from its seat. This design ensures a rapid response to load changes in typical hydraulic circuits while maintaining low internal leakage. Notably, this valve is intended for both existing and new applications, although it is suggested that users consider the RVD58-20 as a superior alternative for most functional replacements due to its enhanced characteristics and competitive cost. However, it should be noted that the GRV10-20 corrosion-resistant version of this valve is not suitable for crossover applications.

Unit weight:

0.23 kg (0.51 lb)

A

0.25 kg (0.56 lb)

B

0.28 kg (0.61 lb)

C/l

0.22 kg (0.49 lb)

F/h

Internal wetted surface area:

133 cm² (20.56 in²)

A b c l

150 cm² (23.25 in²)

F h

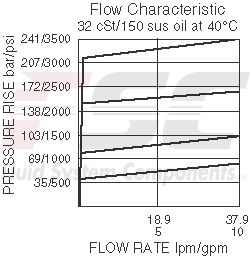

| Ratings | Pressure Ratings Pressure rating: 228 bar (3300 psi) RV10-20X 228 bar (3300 psi) Grv10-20x port 1 34.5 bar (500 psi) Grv10-20x port 2 Proof pressure: 517.1 bar (7500 psi) Burst pressure: 1037.7 bar (15000 psi) Crack pressure defined: Pressure evident at 0.95 lpm (0.25 gpm) attained port 1 to port 2 Reseat pressure: Nominal 85% of crack pressure Relief pressure range: 6.9 to 206.8 bar (100 to 3000 psi) From zero to maximum control current Flow Ratings Flow rating: 38 lpm (10 gpm) At max pressure Maximum internal leakage: 5 drops/min To 85% of nominal setting Temperature Ratings Operating fluid temperature: -40 to 100 °C (-40 to 212 °F) With buna N seals -26 to 204 °C (-15 to 400 °F) With fluorocarbon seals -54 to 107 °C (-65 to 225 °F) With polyurethane seals Storage temperature: -40 to 70 °C (-40 to 160 °F) Ambient temperature: -40 to 70 °C (-40 to 160 °F) Other Ratings Corrosion protection: RV10-20X type III clear zinc plating per ASTM B633 Grv10-20x 960 hour salt spray per ASTM b117 |

| Operating Parameters | Fluids:

Mineral based or synthetic with lubricating properties Fluid viscosity range: 7.4 to 420 cSt Maximum operating contamination level: 18/16/13 per ISO 4406 |

| Performance |  |

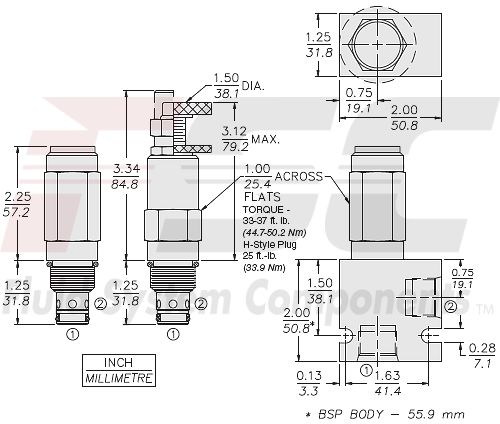

| Installation Specifications | Cavity:

VC10-2 10-size-2-way Cavities Cartridge installation torque: 33.9 to 36.7 N-m (25 to 27 ft-lb) Maximum allowable torque: 67.7 N-m (50 ft-lb) H style plug torque: 33.9 N-m (25 ft-lb) Orientation restriction: None |

| Order Code | POSITION CODE DESCRIPTION RV10-20F-H-J-R/S F Adjustment Option F A 1/4" Hex Allen Head F B 1-1/2" Diameter Aluminum Knob with Aluminum Lock Knob F C 1/4" Hex Allen Head with Cover Cap F F Factory Preset Non-Adjustable F H Factory Preset Hidden Adjustment F L 1/4" Hex Allen Head with Cover Cap and Lockwire Holes H Line Body H 0 No Body H 6T Aluminum SAE 6 H 8T Aluminum SAE 8 H 6TD Ductile Iron SAE 6 H 8TD Ductile Iron SAE 8 H 2B Aluminum BSPP 1/4" (2) H 3B Aluminum BSPP 3/8" (3) H 4B Aluminum BSPP 1/2" (4) H 4BD Ductile Iron BSPP 1/2" (4) J Seal J N Buna-N J NC Buna-N for Crossover Applications J V Fluorocarbon J VC Fluorocarbon for Crossover Applications J P Polyurethane J PC Polyurethane for Crossover Applications J U PPDI Urethane R Spring R 06 3.4 to 41.4 bar (50 to 600 psi) Spring Range R 12 10.3 to 82.7 bar (150 to 1200 psi) Spring Range R 23 17.2 to 158.6 bar (250 to 2300 psi) Spring Range R 33 17.2 to 227.5 bar (250 to 3300 psi) Spring Range S Setting S MXXX Spring Setting in XXX bar S XX Spring Setting in XX psi (x 100) |

Seal kit:

SK10-2X-B

X=seal option

SK10-2X-M

X=seal option

Seal kit installation instructions

Housings:

Available

10-2w valve bodies

| Product ZIP File | Download Product ZIP File |

| Product PDF File | Download Product PDF File |