HYDRAFORCE

5612504NC

$78.54 USD

- HYDRAFORCE

- Material:5612504NC

- Model:RVD50-20A-0-NC-24/ RELIEF

- Summary:RELIEF VALVE

Due to extremely high demand, please call 920-337-0234 for availability

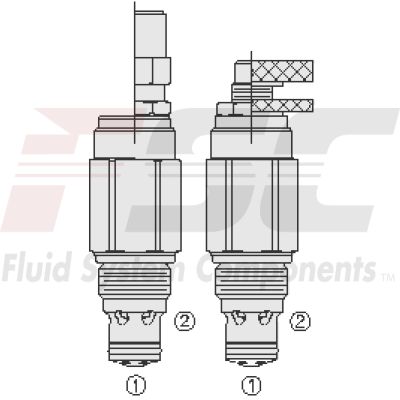

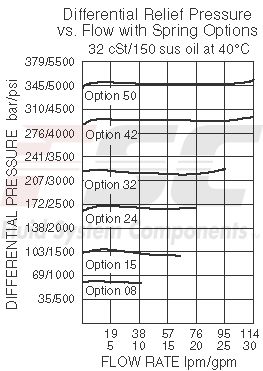

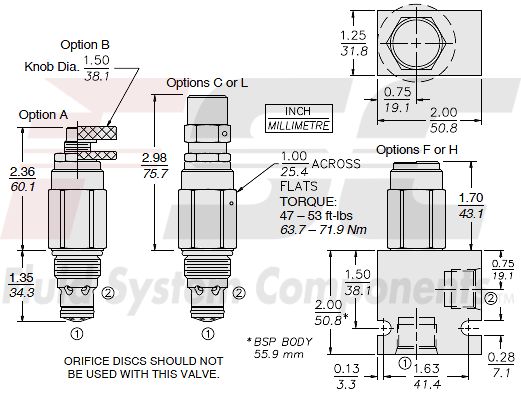

The Hydraforce 5612504NC (5612504NC) is a screw-in, cartridge-style, direct-acting poppet type relief valve designed specifically for use as a pressure limiting device, providing essential protection to hydraulic circuits. This component effectively blocks flow from port 1 to port 2 until the pressure at port 1 reaches a level that forces the poppet off its seat. Notable for its rapid response to load changes, the valve is ideal for applications requiring minimal hysteresis, low pressure rise, and reduced internal leakage. The design ensures that adjustments cannot be inadvertently backed out of the valve, maintaining consistent performance. Additionally, the height of the adjuster remains constant even when pressure settings are modified. Constructed with a hardened poppet and cage, this valve promises extended durability and reliability over time. It also offers optional spring ranges up to 345 bar (5000 psi), catering to various operational needs. Furthermore, it fits into an industry-common cavity, allowing for seamless integration into existing systems without necessitating extensive modifications.

Unit weight:

0.21 kg (0.46 lb)

A

0.23 kg (0.51 lb)

B

0.25 kg (0.56 lb)

C l

0.20 kg (0.44 lb)

F h

Internal wetted surface area:

158 cm² (24.6 in²)

A b c l

151 cm² (23.3 in²)

F h

| Ratings | Pressure Ratings Pressure rating: 413.7 bar (6000 psi) Proof pressure: 785.4 bar (11000 psi) Burst pressure: 1515.8 bar (22000 psi) Crack pressure defined: Pressure evident at 0.95 lpm (0.25 gpm) Reseat pressure: Nominal 85% of crack pressure 1 ml/min (20 drops/min) Flow Ratings Flow rating: 113.6 lpm (30 gpm) Port 1 to 2 at max pressure Maximum internal leakage: 0.25 ml/min (5 drops/min) To 80% of nominal Temperature Ratings Operating fluid temperature: -40 to 100 °C (-40 to 212 °F) With buna N seals -26 to 204 °C (-15 to 400 °F) With fluorocarbon seals -54 to 107 °C (-65 to 225 °F) With polyurethane seals -54 to 107 °C (-65 to 225 °F) With urethane seals Storage temperature: -40 to 70 °C (-40 to 160 °F) Ambient temperature: -40 to 70 °C (-40 to 160 °F) Other Ratings Corrosion protection: 960 hr salt spray per ASTM b117 (grvd50-20x) |

| Operating Parameters | Fluids:

Mineral based or synthetic with lubricating properties Fluid viscosity range: 7.4 to 420 cSt Maximum operating contamination level: 18/16/13 per ISO 4406 |

| Performance |  |

| Installation Specifications | Cavity:

VC10-2 10-size-2-way Cavities Cartridge installation torque: 63.7 to 71.9 N-m (47 to 53 ft-lb) Orientation restriction: None |

| Order Code | POSITION CODE DESCRIPTION RVD50-20F-H-J-R/S F Adjustment Option F A 1/4" Hex Allen Head F B 1-1/2" Diameter Aluminum Knob F C 1/4" Hex Allen Head with Cover Cap F F Factory Preset Non-Adjustable F H Factory Preset Hidden Adjustment F L 1/4" Hex Allen Head with Cover Cap and Lockwire Holes F P PED 2014/68/EC H Line Body H 0 No Body H 6T Aluminum SAE 6 H 8T Aluminum SAE 8 H 6TD Ductile Iron SAE 6 H 8TD Ductile Iron SAE 8 H 2B Aluminum BSPP 1/4" (2) H 3B Aluminum BSPP 3/8" (3) H 4B Aluminum BSPP 1/2" (4) H 4BD Ductile Iron BSPP 1/2" (4) J Seal J N Buna-N J NC Buna-N for Crossover Applications J V Fluorocarbon J HV High Durometer Fluorocarbon J VC Fluorocarbon for Crossover Applications J P Polyurethane J U PPDI Urethane R Spring R 08 13.7 to 58.6 bar (200 to 850 psi) Spring Range R 15 41.4 to 103.4 bar (600 to 1500 psi) Spring Range R 24 96.5 to 165.5 bar (1400 to 2400 psi) Spring Range R 32 137.9 to 220.6 bar (2000 to 3200 psi) Spring Range R 42 206.8 to 289.6 bar (3000 to 4200 psi) Spring Range R 50 275.8 to 350 bar (4000 to 5075 psi) Spring Range S Setting S MXXX Spring Setting in XXX bar S XX Spring Setting in XX psi (x 100) |

Seal kit:

SK10-2X-B

X = n, v, HV, P

SK10-2X-M

X = NC, VC, HVC, PC

SK10-2X-O

X = U

Seal kit installation instructions

Housings:

Available

10-2w valve bodies

| Product ZIP File | Download Product ZIP File |

| Product PDF File | Download Product PDF File |